It’s estimated that more than half of the vehicles on U.S. roads could be EVs by 2050. So the question becomes, are EV car batteries a hazardous waste? And if so, how should they be disposed of? This blog entry discusses the use and disposal of batteries used in EVs through a series of Q&As.

Topics we will cover:

Current State of EV Vehicles in the US

1. What is the current percent of US vehicles that are EVs?

Electric vehicles (EVs) have been available in the US for well over a decade, but their acceptance has been slow. At the moment, they comprise only an estimated one percent of the 250 million vehicles traversing US roads. However, in the first three months of 2022, EV registrations increased 60 percent, even though the overall automotive market was down 18 percent.

2. What percent of the automotive market will be EVs in the future?

It’s projected that 25 to 30 percent of new car sales could be electric by 2030 and perhaps 40 to 45 percent by 2035 (see source). Using those projected rates, Reuters estimates that by 2050, more than half of the vehicles on US roads could be EVs.

EV Battery Manufacturing and Disposal

3. What kind of batteries do EVs use?

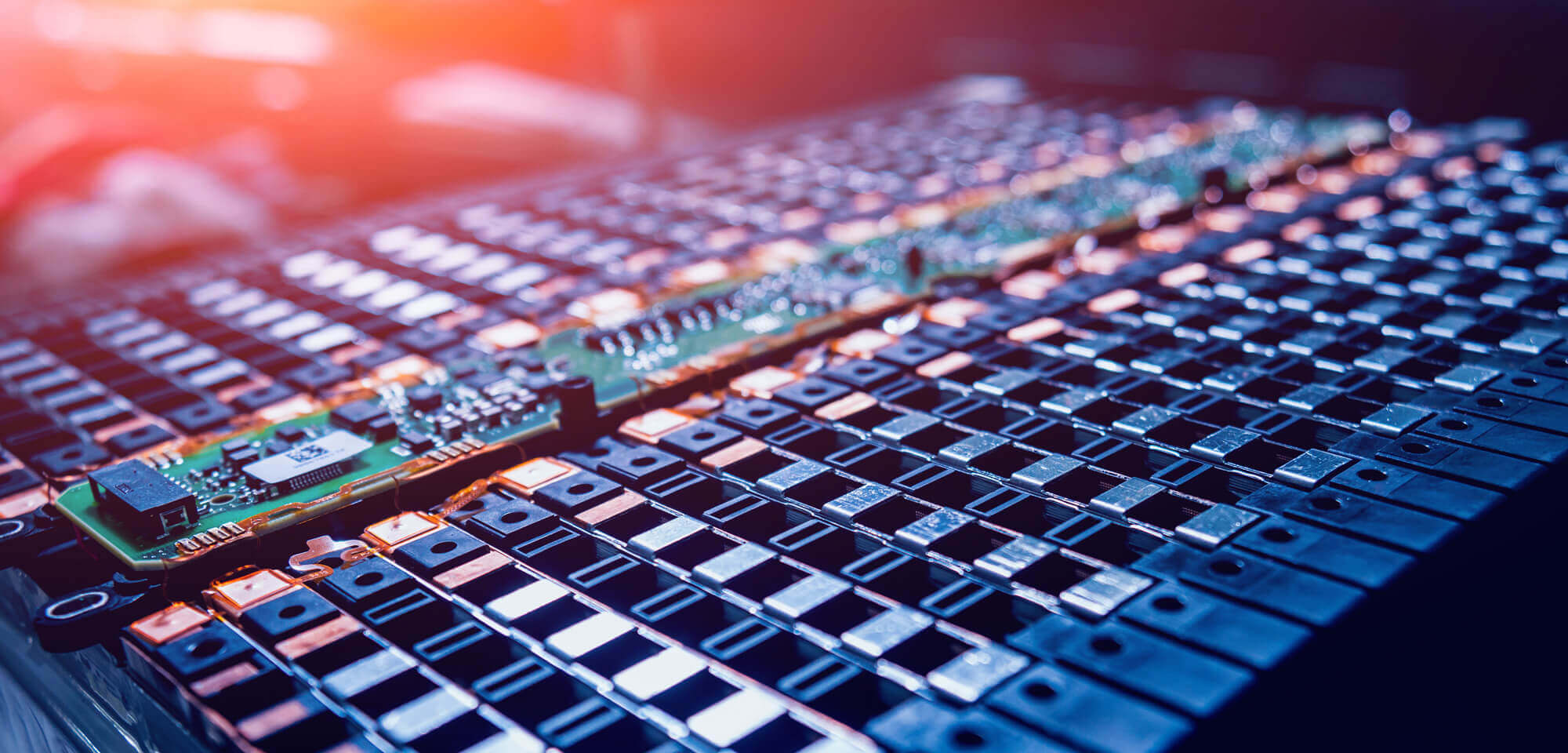

Some electric vehicles use nickel-metal hydride batteries (NiMH), but most new EVs use lithium-ion (Li-ion) batteries, taking advantage of their high energy-density. Li-ion batteries are composed of many hundreds of lithium-ion cells. For example, batteries used in Tesla automobiles each contain 2,976 of them.

4. What are lithium-ion batteries?

Li-ion batteries are composed of hundreds of lithium-ion cells. Like all electric storage cells, a lithium-ion cell contains a positive terminal, a negative one, and an electrolyte. However, unlike other cells, a lithium-ion cell incorporates an insulating “separator” between its terminals that has a special purpose.

When a lithium-ion cell discharges, the lithium ions travel from the positive terminal, through the electrolyte, and on to the negative terminal, but also pass through the separator. This flow of ions creates an electrical potential (aka, voltage).

In non-technical terms, this means there are more electrons at one terminal than at the other, and they want to move so that each terminal has the same amount. But the separator blocks these electrons while letting ions pass.

As a result, the only path around the separator for the electrons is through the circuit that is in series with the load, thus energizing it. In the case of an EV, the load is the car’s electric motor.

5. How are lithium-ion batteries recycled?

Smelting uses high temperature to recover basic elements from Li-ion batteries. End-of-life Li‑ion batteries are crushed and shredded, creating an e-waste called “black mass,” which typically contains such reusable metals such as cobalt (16%), nickel (7%), aluminum (5%), manganese (5%), and lithium (3%).

Black mass is heated to 1,292°F (700°C) to burn off organic materials, the electrolyte, and/or hazardous waste (e.g., fluorine), leaving the valuable metals for later refining. Any other materials (e.g., lithium) are contained in the remaining “slag,” which can be used as an additive in other products (e.g., concrete).

6. What other kinds of batteries are used in EVs?

In lieu of Li-ion batteries, some EVs are equipped with:

- a) Nickel-metal hydride batteries (NiMH). These are typically found in computer and medical equipment. Automotive versions are used to provide electricity for hybrid vehicles, which have an internal-combustion engine to back up their electric motor. As such, the batteries in hybrid autos needn’t be as robust as for pure EVs. Thus, lead-acid batteries can be used. But NiMH batteries get the call because they have a longer life cycle and can take more abuse.

- b) Lead-acid batteries are found in all cars with internal combustion engines. They are used to power the starter motor and electrical accessories when the engine is not running. They’re inexpensive, safe, reliable, and can be designed for high power. However, a low power-to-weight ratio, poor cold-temperature performance, and short charging-cycle curtail their use for hybrid vehicles or EVs.

7. How are NiMH batteries recycled?

NiMH batteries are recycled in a low-temperature process called “direct recovery,” in which they are disassembled into thousands of cells, which are then treated with supercritical CO2, an industrial solvent, to extract the electrolytes. The cells are then disassembled, broken, and sorted in order to collect reusable materials.

8. How are lead-acid batteries recycled?

The acid is removed from the batteries. Then, they are then crushed into nickel-sized pieces that are dropped into a water vat. The heavy materials and the lead drop to the bottom. The plastic (that formed the battery case) floats.

The plastic pieces are scooped up, washed, dried, melted, and then placed into an extruder to creates pellets that are used to make new battery cases.

The lead components are cleaned, heated inside smelters, and then poured into molds. Impurities float to the top and are removed. After the molds cool, the lead is extracted and used to manufacture new batteries.

The battery acid is either neutralized, so it turns into harmless water. Or it’s processed into sodium sulfate and used to manufacture products such as laundry detergent, textiles, or glass.

About Electric Storage Cells

9. What is the difference between an electrical storage cell and a battery

NiMH batteries are recycled in a low-temperature process called “direct recovery,” in which they are disassembled into thousands of cells, which are then treated with supercritical CO2, an industrial solvent, to extract the electrolytes. The cells are then disassembled, broken, and sorted in order to collect reusable materials.

An electric storage “cell” is a single power-generating component made up of three parts: an electrolyte sandwiched between two electrodes. A AAA battery is a good example.

A battery is a group of cells, the word “battery” being a synonym for “group.” The 12-volt lead‑acid battery under the hood of your (non-EV) car is composed of six cells, each nominally producing two volts. So, it’s a “battery” of cells.

10. What is an electricle storage cell?

Electrically speaking, an electrode is simply a piece of metal through which electricity enters or exits an object; and an electrolyte is a chemical liquid or paste that allows an electrical charge to pass between them.

Thus, in a cell, one electrode is marked “positive” (+) and the other “negative” (–). But in which direction the juice flows depends on whom you ask.

Why Proper Disposal is Critical

11. Does the US have the minerals needed to produce lithium-ion batteries?

Probably not. There are concerns about the sustainable supply of battery materials for Li-ion batteries due to the fast growth of the EV market (see source). These include:

High geopolitical concentrations of needed minerals in somewhat hostile countries

Social and environmental impacts associated with mining

Supply chain issues

Thus, the recycling market for Li-ion battery constituents is expected to expand significantly, and black mass will provide strategically important metal resources to battery makers and—ultimately—EV manufacturers.

12. What's the upshot?

EVs will rapidly displace automobiles powered by internal-combustion engines in the coming years. Thus, a tidal wave of end-of-life Li-ion batteries will become an environmental reality.

Such batteries are energy- and labor intense to deconstruct, which will make designing efficient recycling systems difficult, creating economic disincentives that will make it more expensive to use recycled Li-ion materials than to buy their virgin counterparts.

This means that large numbers of Li-ion batteries will not be recycled and therefore require hazardous waste transportation, treatment, and disposal.

As previously stated, if your business owns significant numbers of vehicles, and you are forced to replace them with EVs, either because of availability or government mandate, your future contains a significant hazardous waste management challenge.

When that time comes, remember that there’s a hazardous waste solution to that challenge right here.

Robert Losurdo

President, COO